Description

● For automatic basin faucets

● Push-fit quick connectors are easy for installation

● BASF environmental friendly material

● Super energy saving solenoid valve drive technology, 4 pieces AA alkaline batteries will last 24 months with 3000 circles per month.

● Compact design with small size with a separated waterproof battery pack.

● DC/AC power supply

What’s the faucet control box/control module?

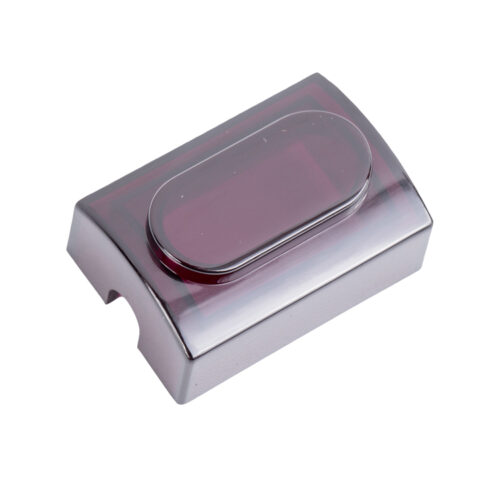

A sensor faucet control box is a square box that sits or mounted underneath the sink as part of a typical sensor faucet installation process. The control box is like a hub which enables water to flow IN (from main water supply) and OUT (to sensor faucet). Most of Rajeyn sensor faucets come with a control box, except 2-IN-1 series such as RJY-11-B201D and RJY-11-B204D. Rajeyn has various control boxes for both basin and kitchen faucets and this page introduces the most classic model RJY-K08-1. It excludes push-fit connectors and used for automatic basin faucets.

The sensor faucet control box RJY-K08-1 includes a solenoid valve and exposed battery case as well as infrared signal wire connection and infrared sensor. All the wires connected to each part are waterproof. The battery pack is built-in design and easy to take out batteries.

# Solenoid Valve

The solenoid valve has a built-in magnetic latching valve that opens and closes whenever an electric signal is sent or received from the infrared sensor. The valve water inlet and outlet size is G1/2”. Valve body is made of plastic while two water connectors are made of brass. The solenoid valve life circle is up to 500,000 on/off. Technical parameters as below.

- Rating voltage: DC6V

- Working voltage: DC4.5V-6.6V

- Type: Pulse valve

- Resistance: 15Ω±0.5Ω(20°C)

- Pulse width: 20ms

- Medium temperature: 1-75℃

- Response time: turn on≤1s; turn off≤1.5s

- Working pressure: 0.05-0.8MPa

- Thread size: G1/2”

# Power Source (battery pack)

This control box is powered by 4 pieces AA alkaline batteries.

# Infrared Sensor

There are over 50 different sensor housings for infrared sensors. They are variety of designs for all-in-one type and separated PCBA. Shapes including round, rectangle, semicircular etc. The sensor function can be tailor-made based on customer’s need.

1. Power supply: DC 4.3~6.4V

2. Static power: ≤0.15mw (≤25uA)

3. Default sensing range: 280mm. Adjustable sensing range: 180mm-380mm (reference: 29.7cm*29.7cm white board). The sensing range error: ±10% of the rated sensing range. Sensor distance adjustable by remote

controller.

4. Max output current: 800mA; Output voltage: 3.9V-6V; Output pulse width: 35ms.

5. Low voltage alarm: Working voltage≤4.4±0.2, sensor indicator flashes to remind replacing batteries.

6. Sensing range stability: Sensing range rangeability is ±5﹪ if working voltage decreases from DC6.4V to DC4.3V; Sensing range rangeability is ±15﹪ if temperature increases from 0℃ to +45℃.

7. Anti-interference performance:

1) There’s no malfunction if more than one systems working together at the same time.

2) There’s no malfunction if there are commonly used electrical appliances nearby.

3) Sensing range rangeability is ±10﹪ with filament lamp slants beyond 1 meter.

8. Shock resistance: hit or beat is not allowed.

9. Direct strong light should be avoided.